Torque Converter Lockup for 1982-1985 Cadillacs Previously Equipped with an HT4100 Engine

If you plan on running your original THM325-4L or 200-4R you'll need some way to lock up the torque converter, or you'll generate excess heat and dramatically shorten the life of your trans (plus buzz the engine on the highway). Thankfully, this is an easy fix. When you get down to it, this is really just a matter of applying +12V to the trans lockup solenoid, but we need to be smart about it.

|

Please Note... The following applies to 1982-85 Cadillacs that were factory equipped with the HT4100 or 350 Diesel. The 325-4L internal wiring is different depending on diesel vs DEFI as you'll see below, but should be consistent across all 3 E-bodies. I've been able to compare the Cad shop manual against the Buick and the 4th gear switch behavior and wiring is the same. I -assume- the Toro was not unique in this regard. If you're swapping in a 200-4R from something else, then all bets are off, and you'll need to consult the diagram for whatever it is it came out of. |

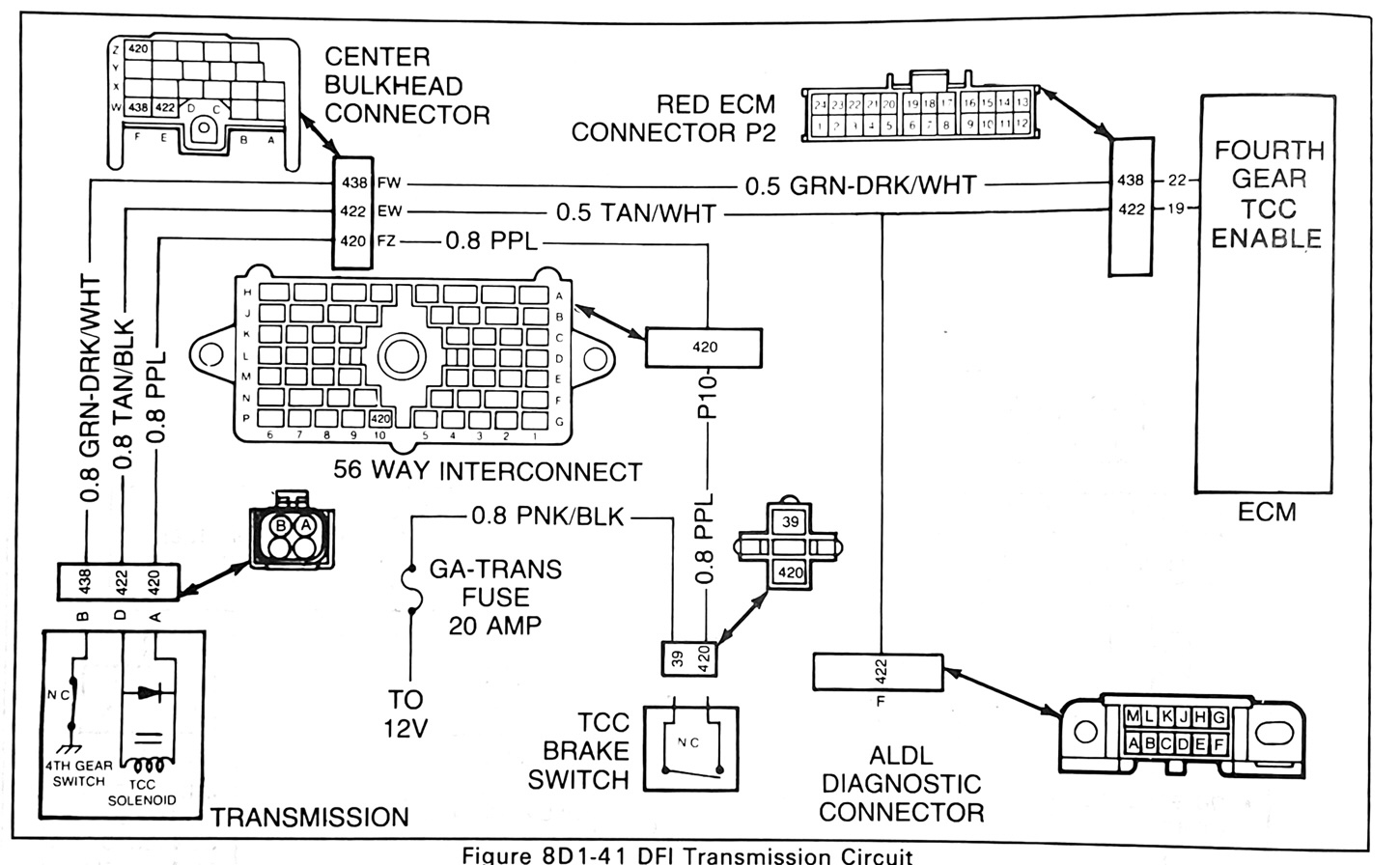

Originally, the HT4100 ECM monitored engine load (manifold pressure), throttle angle, RPM, engine temp, wheel speed, and the brake pedal. Once the trans signaled it was in 4th gear by opening its 4th gear switch, if all parameters were met (engine warmed up, wheel speed >48MPH, etc.), the ECM would energize the torque converter lockup solenoid. Some delay was also built into the software to prevent converter lockup cycling too frequently, such might be the case if engine load was right on the edge of acceptable.

In addition, a dedicated brake pedal switch cuts power to the TCC solenoid to prevent lugging, stalling, and as a fail-safe. Below is the factory wiring diagram; note the 20A Trans Fuse is supplied by -switched- 12V power (ignition ckt).

Click to Enlarge - 1982-1985 HT4100 Shown |

How did the diesel cars do it if they didn't have an ECM?

They used a temperature switch, a vac switch and the brake switch, all wired in series to provide +12V to the solenoid. As long as those conditions were met, voltage flowed to the trans. A governor switch internal to the trans completed the circuit to ground when speed was above 40MPH. Note this switch works the opposite of the gas cars by closing when speed is met.

According to the '84 shop manual, TCC lockup was designed to occur in both 3rd and 4th gears on diesels. My understanding is there are also a number of tuning differences between the diesel and gas version of the 325-4L, though many diesel cars were 'upgraded' to gas back in the day and I'm sure more than one never had the trans or torque converter modified.

Bottom line, the internal trans wiring and TCC functionality is different between the diesel and 4100 cars. And if you're converting a diesel car to gas, you might as well use the diesel TCC wiring and switches, though an adjustable aftermarket vac switch might be wise in placse of the original.

Please Note: I have edited the diagram below based on referencing the overall vehicle diagrams. I believe the original is in error.

Click to Enlarge - 1982-1985 Diesel Shown |

There's a couple approaches you can take to restore the TCC feature on a 4100 car....

1. Toggle Switch wired directly to the converter solenoid that grounds circuit 422. I wouldn't advise that as it'll lug your engine into a stall should you forget to release it or come to a panic stop. If you do go this route, polarity matters. See factory diagram above, and be sure to cut the wiring to the ECM if you're leaving it in place.

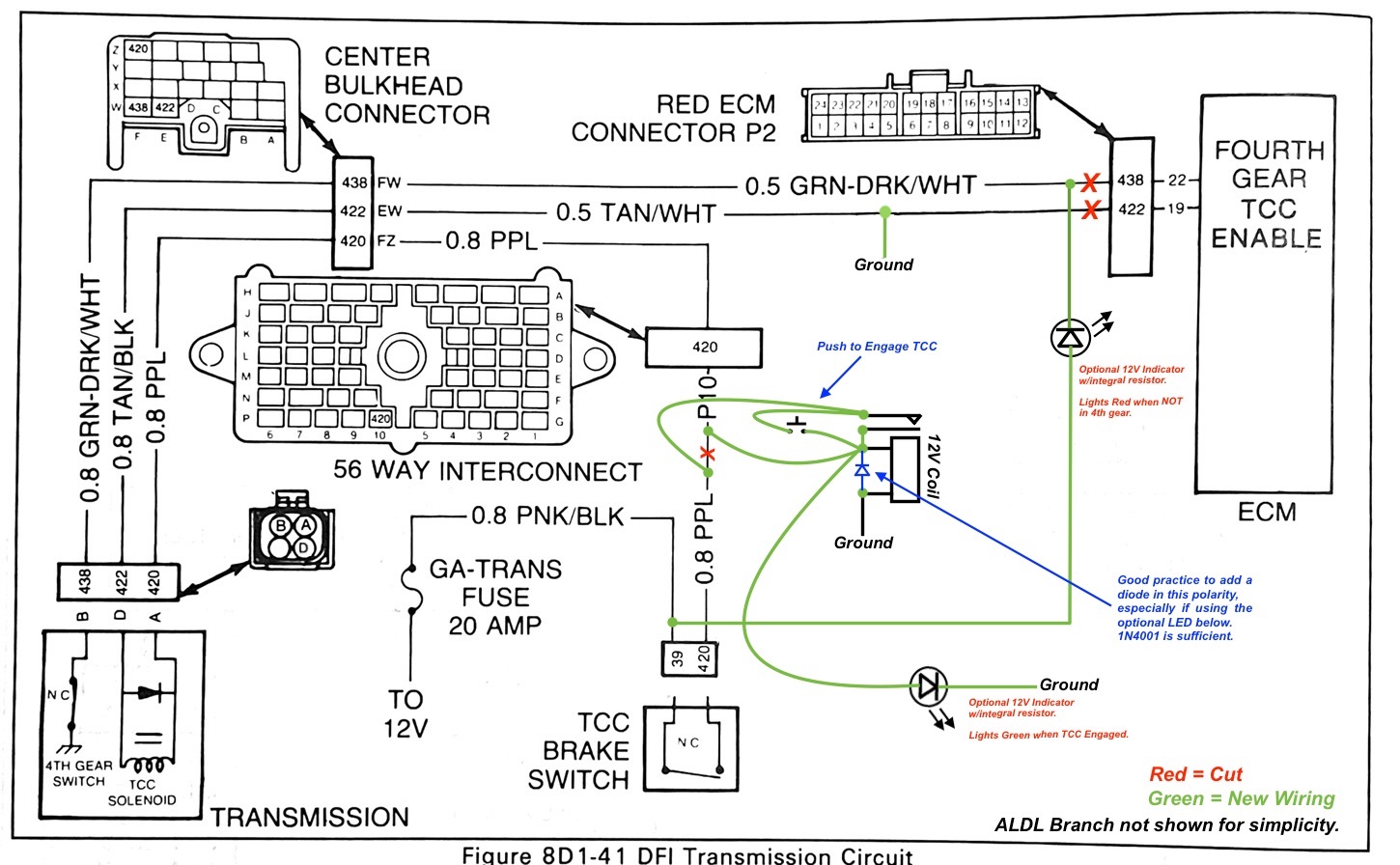

2. Pushbutton and a relay. This is what I did on my first conversion. Once on the highway cruising along, knowing the engine was warmed up and knowing I was above 45MPH and not planning on slowing down anytime soon, a press of a button latched a relay which energized the lockup. A tap of the brake pedal released it. I made use of the internal 4th gear switch by wiring it to a red LED so that it'd light when the trans was not in 4th gear as a 'No-Go' reminder. A green LED wired to the relay coil lit up when TCC was energized. If you take this approach, and decide to use an LED that lights when TCC is engaged, be sure to add a diode across the new relay coil or your LED will have a very short life.

Click to Enlarge - A regular 12V automotive relay does the job. |

3. Aftermarket kits: I see a lot of aftermarket lockup solutions from Jegs, Summit, etc., but few are better than the diesel setup. One looks at vacuum only. Another looks at wheel speed only, but doesn't know if we're in 4th gear or not. And none seem to care about temp. If you want delay to avoid rapid lock/unlocking, some kits offer it, but at greater cost. And almost all require installation of a kit-provided solenoid or switch to bypass factory wiring, which means dropping the pan.

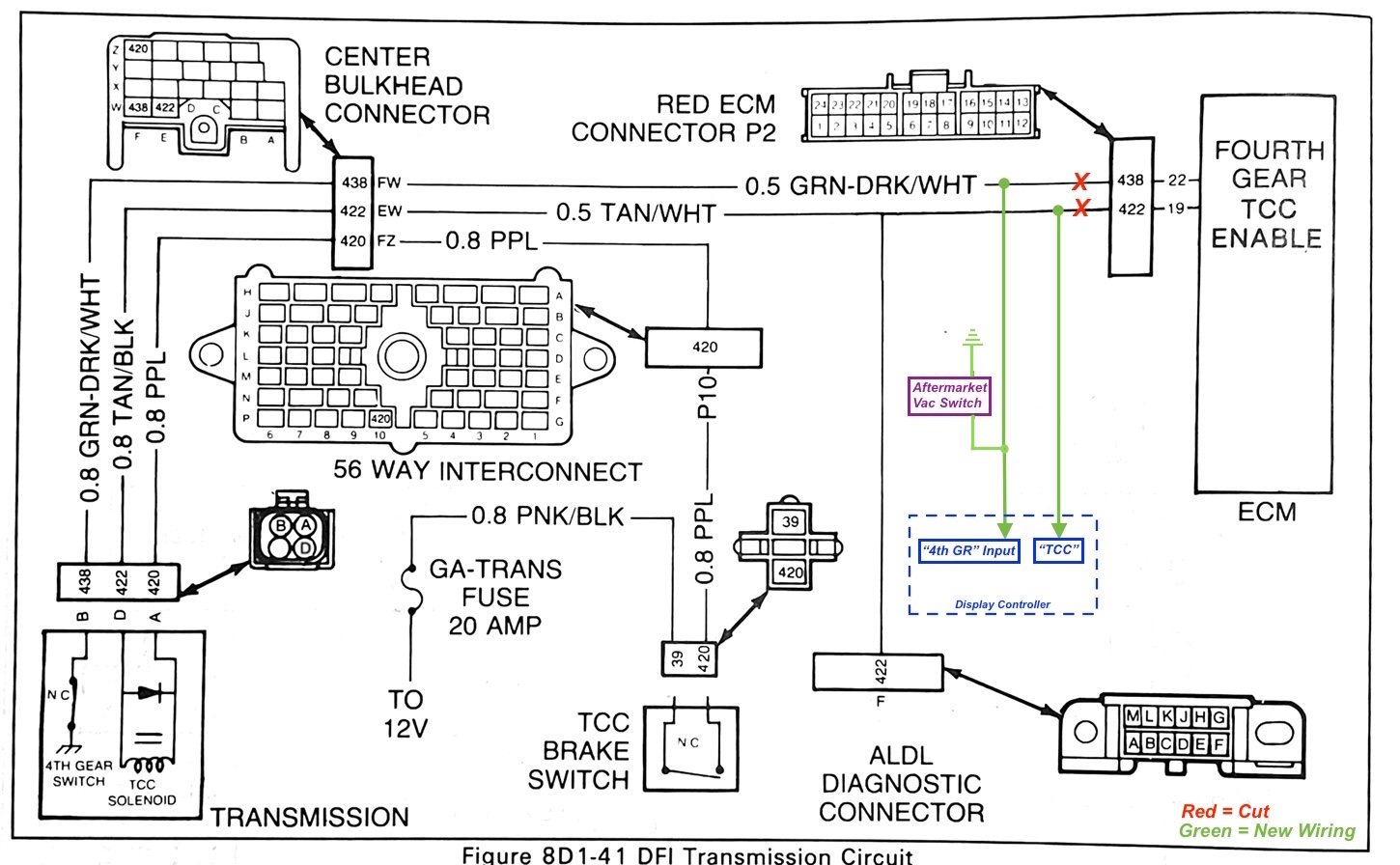

4. Custom Controller: The three solutions above will all work, but I wanted something that was easy to connect and worked like the factory setup, so I designed the following controller which works with the 'normally closed' 4th gear switch, watches engine temp and vac, and has a user-adjustable delay. Plus no need to take an ATF bath installing it. Plus it can drive the Coolant Temp light now that the 4100's ECM can no longer do the job. And the best news is, it's priced competitively with units that offer none of these features. Wiring couldn't be easier. Click Here for Details.

|

Cooked Connector?

|

The original connector is known as a 4-Way Weatherpack, and chances are you may want a fresh one. Just google "700R4 connector" and you'll find tons of options for 10 bucks or less. Be aware, the factory manual, and thus diagrams above, tend to flip-flop between showing the male side and the female side, so go by wire color or check with a meter when ID'ing your circuits. |

|

| Return to Main Page | Corrections? Additions? Contact Webmaster | Cory Heisterkamp 2022 |